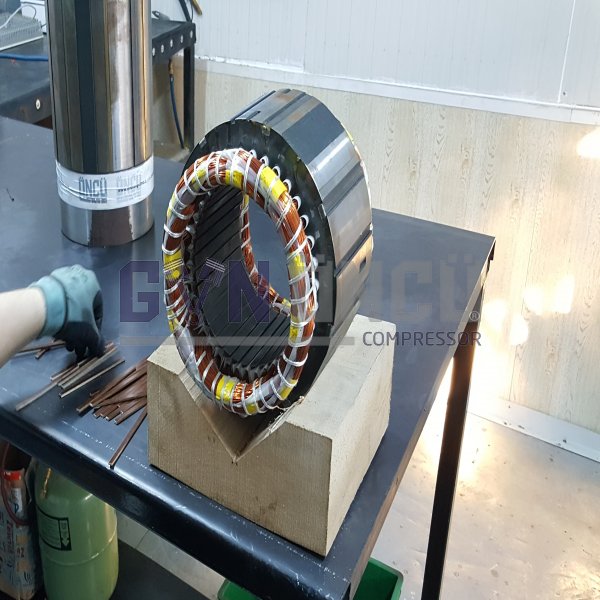

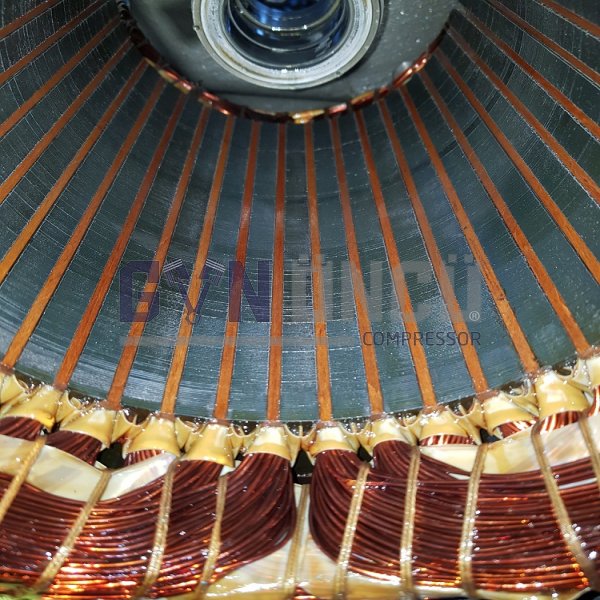

REFRİGERANT COMPRESSOR AND AC MOTOR STATOR WINDING

The main combustion causes of the windings of the cooling compressors are the crankshaft locking due to voltage fluctuations, phase failure and mechanical failure. Due to their duty, the refrigerant compressors which are subjected to higher peak currents than the electric motors are in contact with the stator sheet package, compressor oil and freon gas. For this reason, insulation is provided on the enameled wires of HCO temperature class which we use in stator sheet package with Freon gas compatible varnish. Windings are protected by suitable thermistor usage. The secondary materials used in windings are selected in accordance with the characteristics of the cooling compressors.

AC (ALTERNATİF CIRCUIT) MOTOR WINDING : Electric motors are made with durable materials. Nevertheless, the load characteristics and operating conditions, the ambient temperature of the motor, the humidity, the dust and so on. environmental factors affect the engine in the negative, causing it to malfunction over time. With the necessary monitoring and effective maintenance methods, however, both the motor becomes completely unusable and the motor can be prevented from operating inefficiently. The main causes of combustion of motor windings are listed below.

1-Sudden voltage increase

2-Undervoltage, high voltage or unbalanced voltage

3-Deactivation of one or more of the motor phases

4-Use outside the engine operating instructions

5-Leave the engine brake in the locked position

6-Overload (working above the rated load for a long time)

7-Incorrect electrical or mechanical assembly

8-Load problem by bed

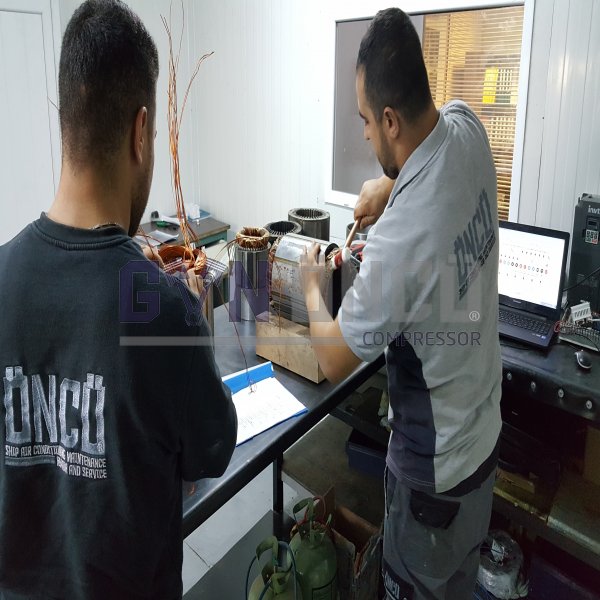

Among the reasons we have mentioned, the reason for the highest burning of the wound is mechanical reasons. We have analyzed these problems well with our extensive R&D studies. We carry out all the mechanical works with our specialist engineers and technicians in the light of our maintenance-repair process which we have examined by examining the engine of burning we have undertaken.