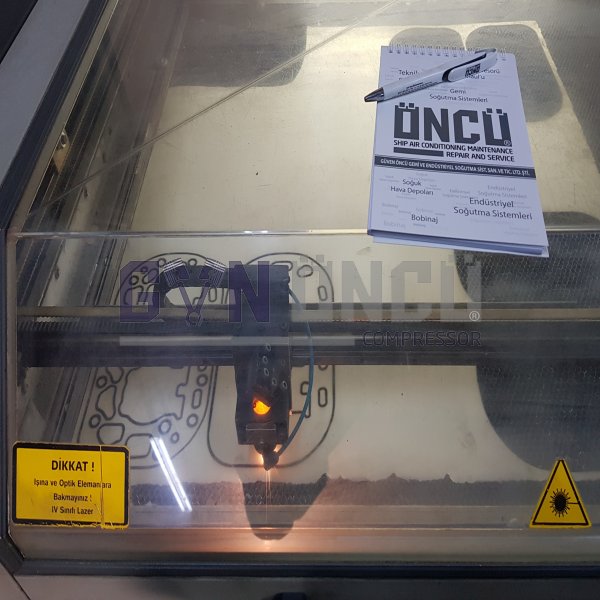

ÖNCÜ Vessel Air Refrigeration Repair And Maintenance is an integral part of cooling since the start of the operation, making the compressor overhoul in its own unit. In order to share his knowledge and experience during this time, he decided to apply compressor overhoul more actively. Thus, we will increase our customer satisfaction by meeting expectations and needs, reach professionalism at what we do, and benefit our economy by reducing the use of imported inputs in our country.

The defective compressor passes through the following stages;

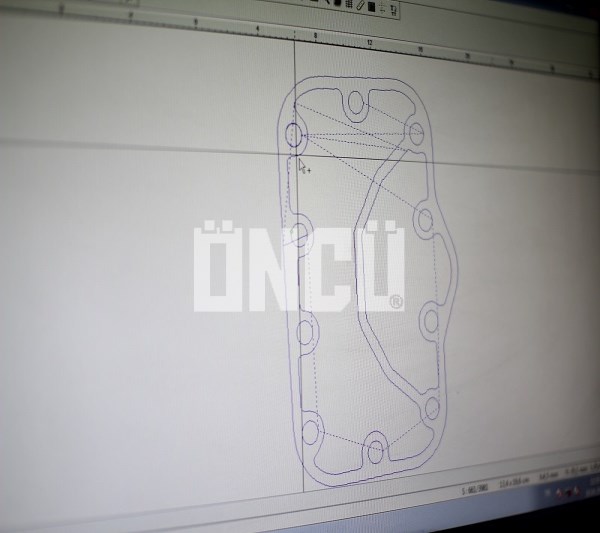

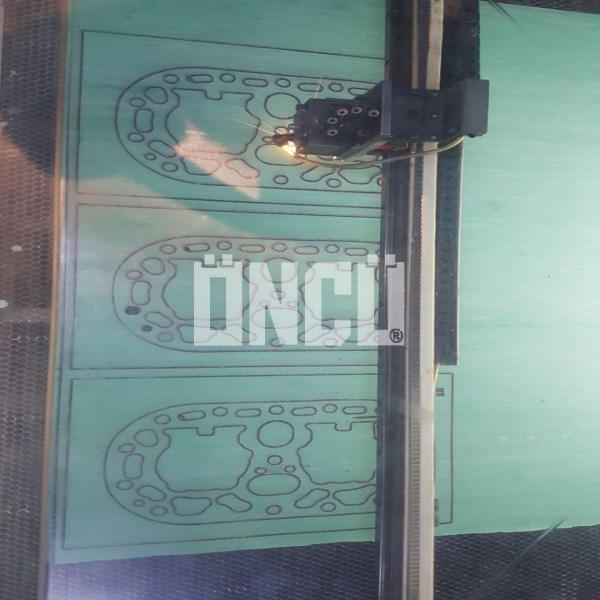

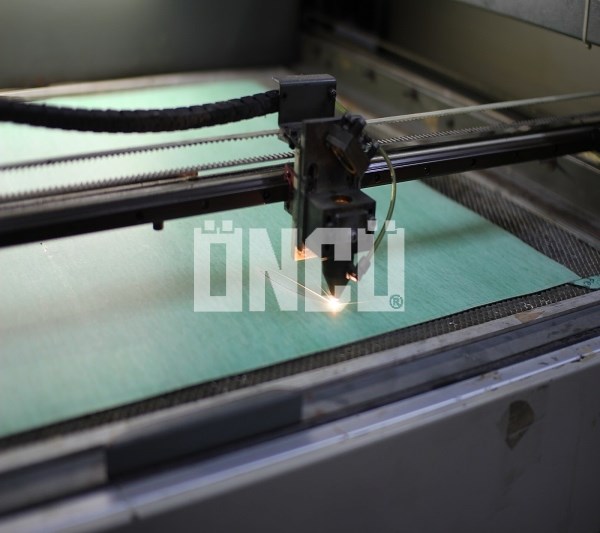

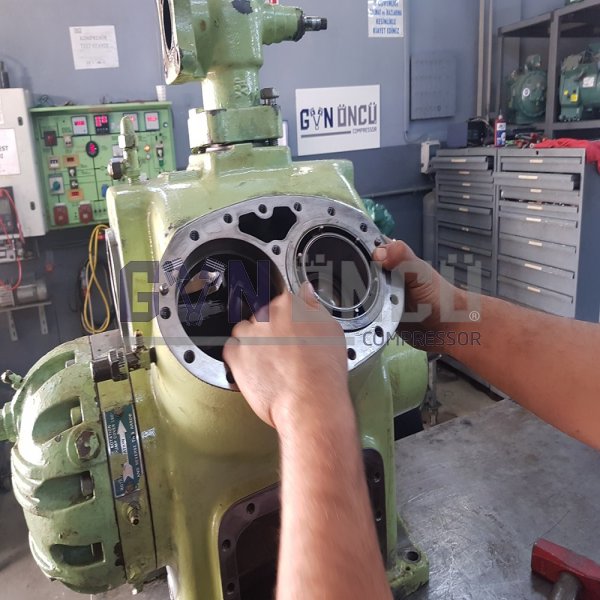

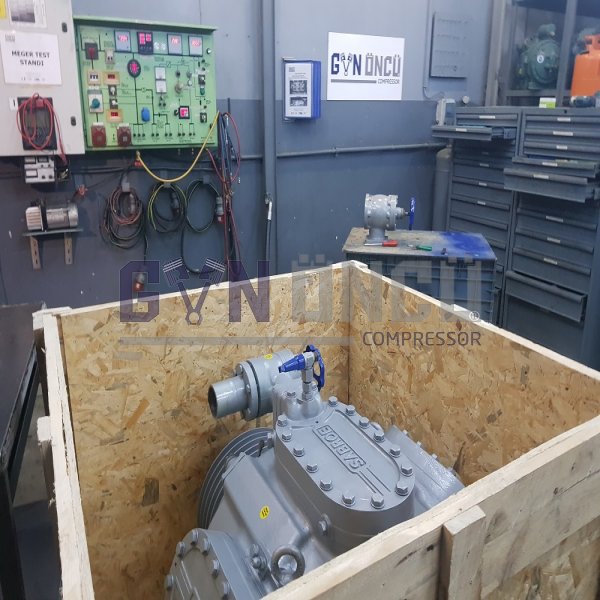

The defective compressor is demounted by our technical team. The removed mechanical parts are subjected to technical measurements and checked to see if they are within the factory wear limits. The required piece can be renewed and collected. The completed compressor is run on the test stand. Amper test, meger test, lubrication pressure check, vibration tests and detailed stator checks are done. Leakage control is performed by pressing nitrogen gas. The compressor which has passed all the controls becomes ready after the paint is done.Processes of the compressor are illustrated and a technical report is prepared and delivered to our customers by e-mail. The modified parts of the compressors and the checklist where the measurement results are made are delivered to our customers together with the revised compressor.